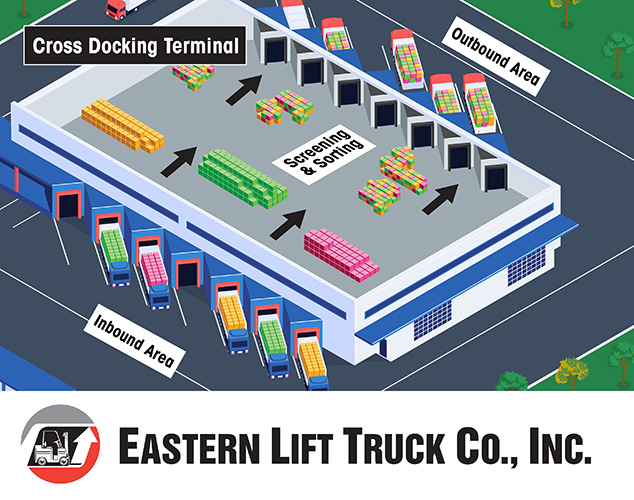

Cross-dock operations are purposely designed to move product quickly, without long-term storage. When deliveries arrive by truck or railcar, product is unloaded and moved to a staging area. There it is screened, sorted and reconfigured on pallets with other product, and then (usually) promptly reloaded onto outbound trucks or railcars and sent on its way again.

A well-run cross-dock facility is in near constant motion. Deliveries come and go. Inside the building, product is moved by lift trucks, conveyors, or a combination of the two. Since the goal is that nothing sits for long, product is not placed in pallet rack. Instead, it typically just sits on the floor. With people, products, and material handling equipment all in motion, and often in tight quarters, it is wise to be extra vigilant when visiting or working inside a cross-dock operation.

Depending on the total number of dock positions, cross-dock facilities may be designed in the shape of an I, T, H, or X to optimize dock placement and overall product flow. Older facilities are usually just long narrow rectangular buildings with rows of dock doors on opposing walls with forklifts buzzing back and forth, and sorting operations in between.

While this type of distribution has been around for years, cross-docking has gained proponents over the past few decades. For example, as e-commerce has intensified consumer demand for faster and faster delivery times, competing retailers added local facilities to handle what has been termed “last-mile” delivery service.

Cross-docking is not just for retail. It appeals to any business attempting to achieve “just-in-time” deliveries and reduce the costs that are inherent with storage and order picking. Cross-docking is a consideration for many involved with high-volume, in-demand, or perishable products. Another benefit of this distribution method is that fewer overall touchpoints result in reduced product damage.

If you have visited a cross-dock operation, you may have noticed they use different types of forklifts. Some may operate sit-down electric or internal combustion forklifts, while others rely on electric pallet jacks or low-level order pickers. Eastern Lift Truck Co. offers all of these types of material handling products, as well as conveyor systems, dock and door equipment and support services for each.

If you have a cross-dock operation, partner with a material handling company that is able to keep up with your fast pace. Eastern Lift Truck Co. is at your service!