How To Maintain A Forklift

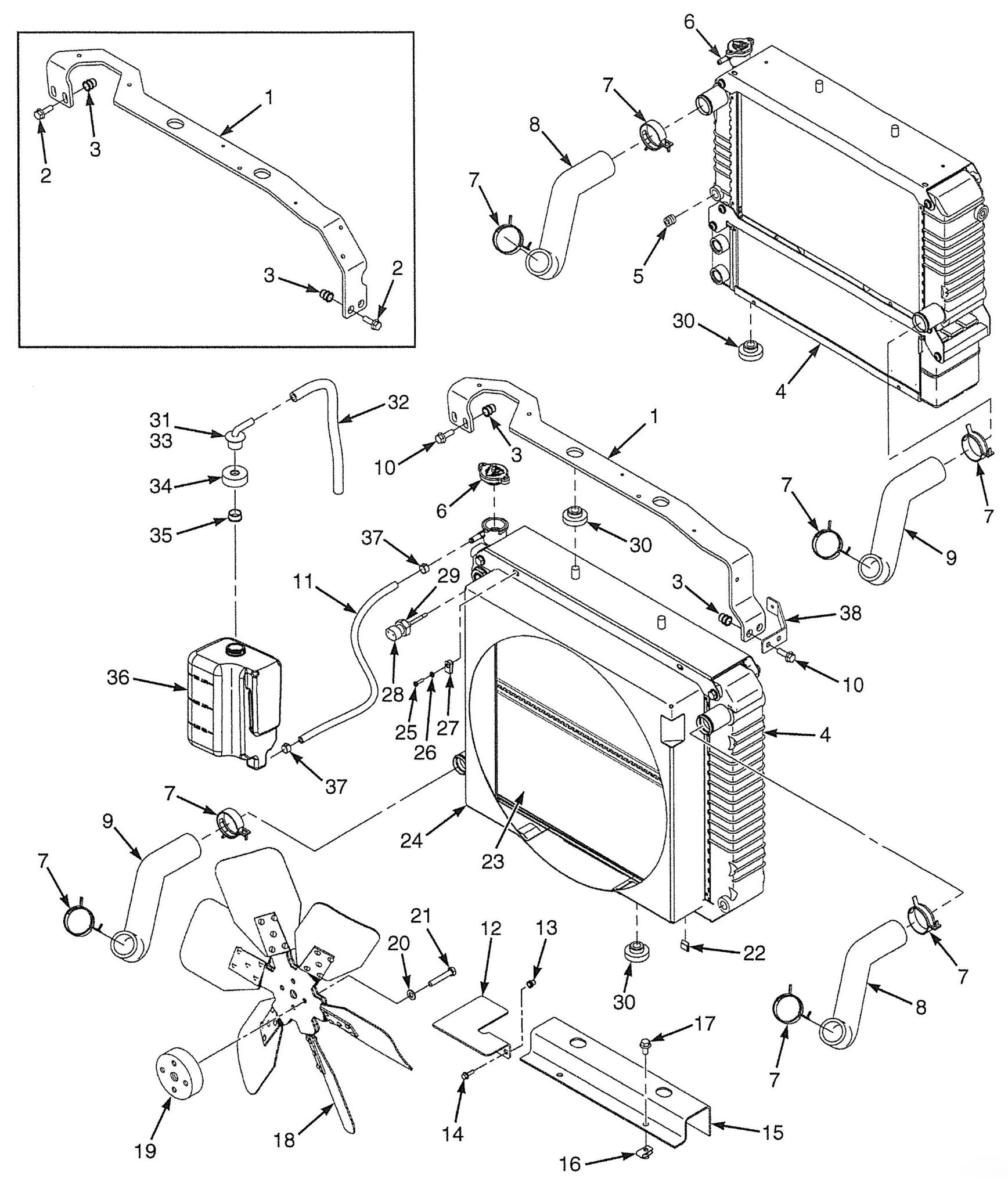

The cooling system in your forklift truck is designed to maintain ideal engine operating temperatures and offset the tremendous heat that is produced during the engine combustion process. When a cooling system is not properly maintained it puts critical engine components at risk. Overheating leads to rust, corrosion, and even engine failure. Ironically, in liquid propane gas forklifts, low coolant levels often cause propane fuel regulators to freeze up.

One of the first components of the cooling system that should be inspected is the radiator. Check for low coolant, cracks, leaks, and corrosion. Radiator screens clogged with dirt or debris need washed or blown out with compressed air.

Coolant hoses wear over time, often from the inside out. Inspect for leaks on a regular basis and replace hoses at suggested service intervals. (Refer to your forklift operator’s manual or contact Eastern Lift Truck Co.’s Service Department for guidance.) Leaks result in a loss of coolant over time, increase engine temperature and lower performance. A hose failure and the resulting spill can produce a hazardous situation for the work place.

Eastern Lift Truck Co., Inc. offers planned maintenance service to help you keep your forklift and its cooling system working efficiently. A typical check-up includes:

1. Check for leaks

2. Check coolant levels

3. Inspect radiator for dirt and debris and clean out as needed

4. Test fan belt for tension and wear

Contact your Eastern Lift Truck Co. Customer Service Representative for more information.