Your industrial lead-acid forklift battery has been examined by a professional and determined to be beyond repair consideration. So, you need replacement battery, and fast. Now what?!

The easy answer is to contact Eastern Lift Truck Co. We’ll send out an Account Manager or Customer Service Representative to gather the necessary information we need to present a quotation for a suitable replacement battery, and get your 4-wheel electric forklift or 3-wheel electric forklift operational again, as soon as possible.

Here is the information we need before we can work on replacing your industrial battery:

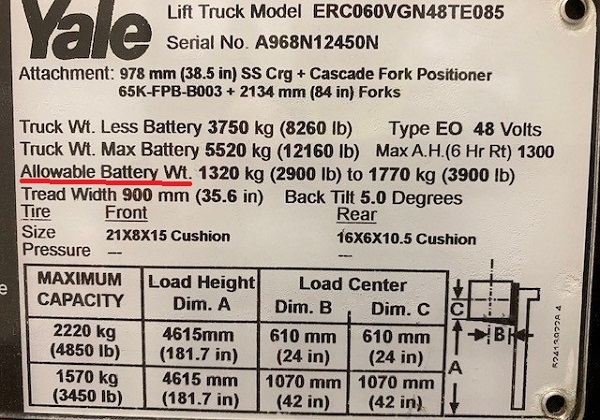

(1) The make, model number, serial number, and voltage of the forklift. This basic information is located on the forklift manufacturer’s data plate, aka the capacity plate. Taking a clear photo of the data plate is always a good idea for future reference.

(2) The minimum and maximum battery weights, as listed by the forklift manufacturer. This information is also on the forklift data plate. Getting the battery weight right is critical since the battery is usually an integral part of the counterweighting that allows your forklift to operate within its capacity specifications.

Next, grab a tape measure, and put on safety glasses and gloves, before proceeding. Open the hood on the forklift (if it has one) to gain access to the battery.

(3) Make a note if the exterior of the battery or the battery compartment appears to be covered in battery acid and/or corrosion. Battery corrosion is the toxic white or bluish substance found on batteries that have spilled acid (electrolyte) in the past. Be very careful, as these substances will burn your skin and eyes, and destroy your clothing.

It is important that any acid or corrosion be properly removed before a replacement battery is installed. This involves pressure washing and should be completed in a suitable and environmentally friendly wash bay. Make a note if your forklift needs to be cleaned. Don’t worry if it does. It is highly recommended to wash and clean your forklift during this process.

Something else to keep in mind: if your battery is severely corroded and acid has found its way down under the battery, there may be hidden damage to hoses or other componentry. When Eastern Lift Truck Co. technicians replace batteries, they check for these types of issues and address any concerns with you before proceeding.

(4) Next, you want to record the make, model serial number and measurements of your failing battery. Most batteries have a data tag or sticker with this helpful information. You may also locate the model number stamped into the battery casing, although this may be a bit more challenging to locate than the tag or sticker. Also note if your company has a preferred brand of battery or if you are open to different battery options.

(5) Measure the battery length across the top of the casing, from one lifting eye to the other – outside dimension to outside dimension. In a sit-down forklift, this dimension runs across the forklift from one side to the other, left to right.

(6) Using the same example of a sit-down forklift, the battery width is measured from front of the battery (nearest the front of the forklift) to back or rear of the forklift.

(7) Getting the height of the battery can be a bit tricky. You’ll need to be sure your tape measure reaches the very bottom of the battery compartment and is hitting a battery spacer or resting on any debris (corrosion, pens, paper, etc.) that has fallen into the compartment since it was last cleaned. Measure to the very top of the lifting handles, or highest point on the battery case. If the battery has a cover (aka lid) make sure your measurement includes it.

(8) While you are inspecting the battery, take a moment to review how you water it. If you are still watering individual cells by hand, your employees run a greater risk of coming into contact with acid and/or accidentally overfilling cells. Overfilled cells result in boil-over, unbalanced electrolyte levels, and a build-up of corrosion, which greatly reduces battery life.

Eastern Lift Truck Co. offers a variety of battery watering options and accessories such as single-point watering systems and battery watering carts and guns, to improve your overall battery safety and environmental cleanliness.

Single-point battery watering systems are now common and easy to use. After a water hose is connected, a valve is opened, and in just a few seconds the entire battery is watered, with each individual cell filled to the same accurate level. The process greatly reduces time spent on battery care and extends battery life.

Despite everyone’s best efforts, lead-acid battery spills may still occur. It would be beneficial to invest in a spill containment kit and make sure your battery maintenance area(s) are equipped with a working eye wash station for your personnel to use.

(9) If your current battery has a single-point watering system installed and you would like a similar system on your new battery, take a photo of the water supply connection, so it may be reviewed and matched on the new battery.

(10) Do you want blinky lights on your replacement battery? If so, make a note of it. Blinky lights are another popular battery option offered by Eastern Lift Truck Co. They provide a simple visual warning when electrolyte levels drop too low in individual cells.

(11) At this point, measure the battery compartment and note if it currently incorporates spacers. When batteries are undersized, or don’t completely fill the battery compartment, spacers are used to secure the battery from moving within the compartment. Unsecured or improperly secured batteries are dangerous, as they may shift and come out of the forklift during operation.

(12) Next, check the battery cables and connections for damage. Note any issues.

(13) Measure and record the overall length of the battery cables and note what length is optimal to reach your battery charger. Only measure what protrudes from the battery tray. Now, is also a good time to consider if you will be keeping your battery charger in the same location or moving it. Talk to your material handling provider about options for moving your charger.

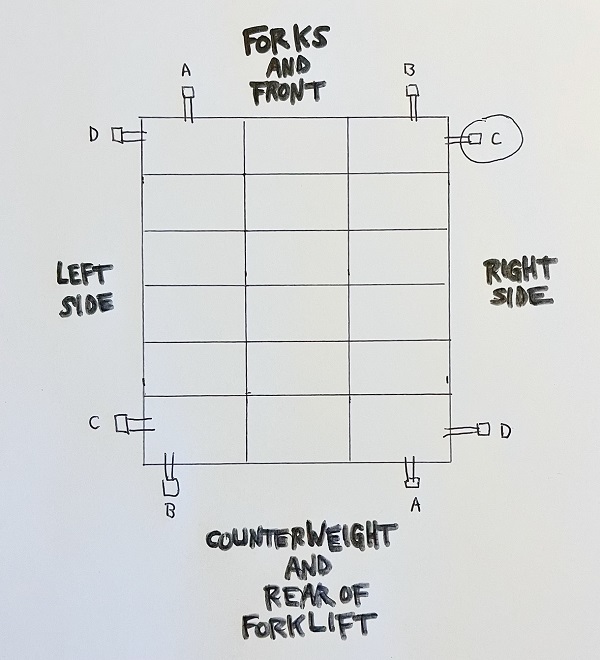

(14) Next, note where the battery cables are attached to the battery. Draw a simple diagram to show the battery in relation to the front of the forklift and place an “x” or circle where the battery cables are attached. Something similar to this example will work.

(15) Note the amperage and color of your battery connector. Two common amperages are: 175-amperage and 350-amperage. This information may be found stamped into the plastic housing of the connector. Your connector may state SB175 or SB350. Connectors come in a variety of colors but are usually grey, blue, or red. Getting all of this information correct is important, as connectors with different amperage and colors are not interchangeable.

(16) Now list the make, model number, and serial number of the charger that is matched with the battery. Make a note if you utilize traditional or opportunity charging, or plan to make changes.

(17) Despite it being last on our list, collecting the following charger information is critical. Jot down your charger’s AC input voltage (208v, 240v, or 480v) and note if the wiring is single or three phase. It may be abbreviated as “1 ph” or “3 ph” on the charger data plate. Like you did for the battery, list any concerns about the condition of the charger cables and note the charger connector type and color (see step 15).

It’s a lot to review, but having all of this information will expedite your battery ordering process and help your material handling provider quote the proper battery replacement, and offer suitable battery options that fit your forklift, application, budget, and timeframe.

If you are interested in learning more about industrial battery safety and other measures to make your operation safer and OSHA compliant, please contact Eastern Lift Truck Co.’s Training Dept.

If you have any questions about what type of industrial battery is best for your material handling equipment, or would like a proposal, please contact an Eastern Lift Truck Co. Account Manager. Our team is always happy to assist.