- Improving safety and environmental cleanliness

- Protecting your employees from contact with battery acid

- Filling to correct heights to prevent acid boil over and lost capacity

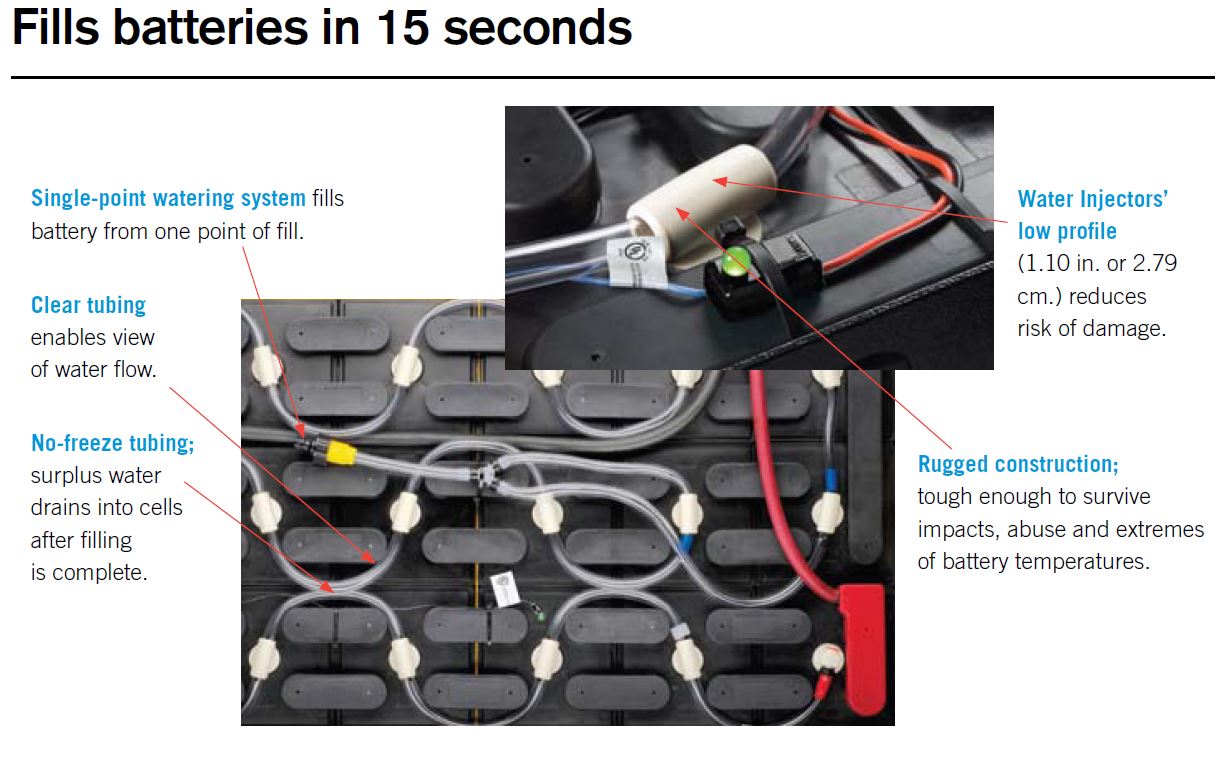

- Simple to Use: Operator makes a hose connection, opens a valve, and in 15 seconds or less the entire battery is watered – Filling every cell to the same accurate level each time

- System saves money in two ways: Cuts labor time, costs and extends battery life by filling batteries to the proper levels every time

Recommendations:

- Make sure that your input/operating water pressure is within the specified psi for the watering system (normally low pressure watering systems are the way to go)

- Individuals should still wear safety goggles and gloves while operating the watering system

- Add a blinkie light to warn you if water is needed

Without a watering system, lost time and hazardous situations could arise.